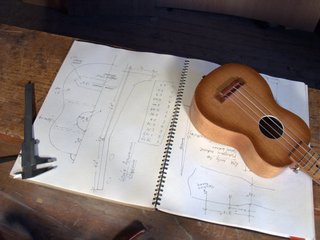

Concert ukulele with redgum and birch rope binding

To build a design base, make notes and drawings of every uke you see.

Gas fired bending iron.

Alternate electric bending iron

Using the formwork to iron out the bumps

Bandsaw angle cut to shape neck blank

A good quality woodrasp will make short work of shaping the neck.

End sanding the neck joint before dowelling

Glueing the neck to the body

Resawing the back panel pieces ready for glueing together.

Resawing rope binding stock

At last, the final finish

Here are a few shots from the workshop. Bill makes acoustic ukuleles, mainly using Australian timbers, because of their good sound characteristics. He also makes a range of solid body electric bass ukuleles. Don't be fooled by the size of these basses, they pack a real punch.

Click the book for a look.

Workshop video tips

Here

Here